Reviving the Industrial Workhorse: Modernizing Modbus with Skysens AgPM

In the flashy world of Industry 4.0, we often talk about AI, Digital Twins, and 5G. But dig a little deeper into any factory floor, and you find the true heartbeat of industrial automation: Modbus.

From energy analyzers installed in the 90s to modern Variable Frequency Drives (VFDs), Modbus is the universal language of operational technology (OT). However, "speaking" the language is only half the battle. The real challenge is liberating that data—extracting it from isolated, wired cabinets and feeding it into a modern, AI-driven platform where it can actually drive predictive insights.

Skysens Agile Predictive Monitoring (AgPM) bridges this gap. It isn't just a wireless sensor platform; it is a comprehensive industrial data engine designed to ingest, contextualize, and analyze data from any source—including your legacy Modbus assets.

Here is how AgPM modernizes your Modbus infrastructure without requiring a "rip-and-replace" overhaul.

What is Modbus TCP? (And Why Does It Still Matter?)

Before we dive into the solution, it is vital to understand the technology we are modernizing.

Modbus was developed in 1979 by Modicon (now Schneider Electric) for use with Programmable Logic Controllers (PLCs). It persists today because it is openly published, royalty-free, and incredibly simple to implement.

Modbus TCP is simply the Ethernet adaptation of this classic protocol.

-

How it works: Instead of sending data over serial copper wires (like Modbus RTU), Modbus TCP wraps the Modbus message inside a standard TCP/IP packet. This allows it to travel over standard Ethernet cables, switches, and even the internet.

-

The Architecture: It uses a Client/Server model. The Client (e.g., Skysens AgPM) sends a request to a Server (e.g., a PLC or Energy Meter) to read or write specific data registers.

-

Where it lives: You will find it in almost every industry—controlling HVAC systems, monitoring power quality in substations, and managing production lines.

Despite its ubiquity, Modbus TCP often creates "data silos." A PLC might know a motor is overheating, but that data often stays trapped on the factory floor, invisible to the maintenance teams who need it most.

The AgPM Approach: 3 Strategies to Unify Your Data

Skysens AgPM eliminates these silos by acting as a central "Universal Translator" for your facility. It integrates Modbus data using three distinct, flexible strategies to fit your specific architecture.

Strategy 1: The Direct Line (Integrated Modbus TCP Client)

Best for: Assets already connected to your local network (LAN).

If your equipment is already on the factory network, you don't need any new hardware. Skysens AgPM features an integrated Modbus Client capability that allows the platform itself to reach out and talk directly to your devices.

-

How it works: You simply configure the IP address and register map of your PLC or analyzer within the AgPM interface. The platform connects via TCP/IP and starts polling data immediately.

-

The AgPM Advantage: This is a pure software solution. It requires zero physical installation downtime. You can instantly bring a 10-year-old chiller online and start applying AI anomaly detection to its temperature readings.

Strategy 2: The Wireless Bridge (Modbus via LoRaWAN)

Best for: Stranded assets, outdoor equipment, or hard-to-wire locations.

This is where AgPM's "Agile" nature truly shines. Many valuable assets communicate via Modbus RTU (RS485) but are located in basements, rooftops, or remote pump stations where running Ethernet is impossible or prohibitively expensive.

-

How it works: You connect a Modbus-to-LoRaWAN bridge to the asset's serial port. This device reads the registers locally and transmits the data wirelessly as secure packages over long distances (up to 15km).

-

The AgPM Advantage: The Skysens platform automatically "unifies" these fragmented wireless packets. It stitches the sensor data back into a coherent asset profile, giving you the reliability of a wired connection with the flexibility of wireless deployment.

Strategy 3: The Unified Namespace (MQTT & Gateway Integration)

Best for: Complex environments with existing automation layers (SCADA/DCS).

In sophisticated facilities, you might already have a gateway or server aggregating Modbus data. AgPM doesn't need to reinvent the wheel; it can simply tap into that stream.

-

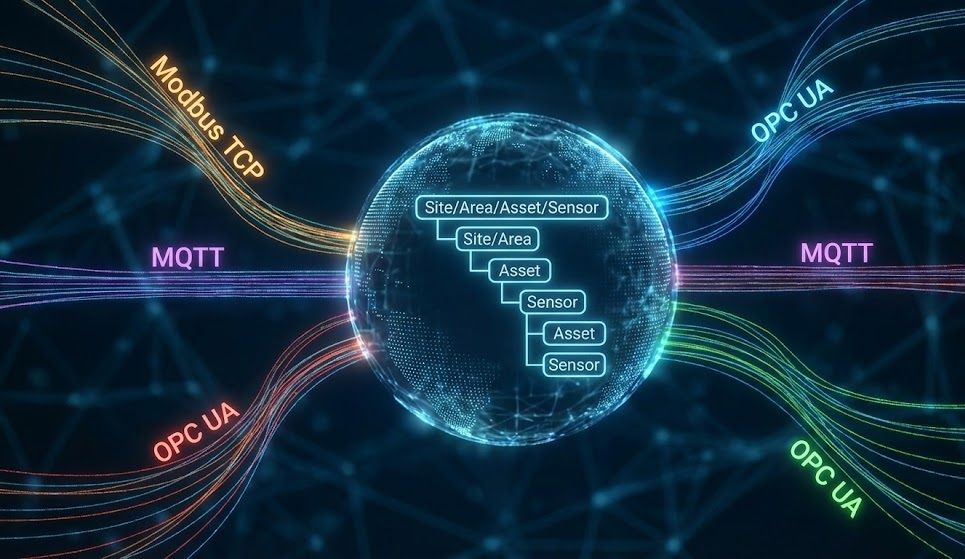

How it works: AgPM connects to your existing translators or edge gateways using modern IIoT protocols like MQTT, Profinet, or OPC UA.

-

The AgPM Advantage: This enables a Unified Namespace (UNS) architecture. AgPM becomes your "Single Source of Truth," normalizing data from thousands of Modbus registers alongside data from wireless sensors and ERP systems.

The Bigger Picture: Building a Unified Namespace (UNS) with AgPM

While connecting Modbus devices is the first step, the ultimate goal of modern industrial architecture is to break down data silos completely. This is where Skysens AgPM’s Unified Namespace (UNS) capability becomes critical.

Traditionally, Modbus integration creates a "spaghetti" architecture: the SCADA system polls the PLC, the Historian polls the PLC, and the ERP asks the Historian. This creates tight coupling and bandwidth issues.

Skysens AgPM flips this model.

Instead of creating another point-to-point connection, AgPM acts as a central Data Hub that structures your raw Modbus data into a standardized, readable hierarchy (often following ISA-95 standards like Site/Area/Line/Machine/Sensor).

How AgPM Transforms Modbus into UNS:

- Contextualization: A raw Modbus register reading of 4001: 85 is meaningless to an IT system. AgPM allows you to map this register once and republish it to the UNS as Factory_1/Boiler_Room/Pump_3/Temperature: 85°C.

- Publish/Subscribe Model: Once the data is in AgPM, it is published to the UNS. Any authorized application—whether it's your ERP, a third-party AI tool, or a maintenance dashboard—can simply "subscribe" to that data stream.

- Decoupling: Your applications no longer need to know how to talk to a 20-year-old Modbus PLC. They just need to know the topic name in the UNS. AgPM handles the translation, protecting your legacy hardware from being overwhelmed by multiple data requests.

By using AgPM as your UNS gateway, you turn a static Modbus register into a dynamic, real-time asset that powers the entire enterprise.

Why Use AgPM for Modbus?

Connecting to Modbus is easy; using the data is hard. Skysens AgPM transforms raw register values into actionable business insights.

- Contextual AI: AgPM doesn't just display a temperature; it understands context. It knows that "High Temperature" on a steam trap requires a different maintenance action than "High Temperature" on a server room AC.

- Predictive, Not Reactive: By feeding legacy Modbus data into AgPM's AI agents, you can predict equipment failures days or weeks in advance, rather than waiting for a red light on a control panel.

- Unified Dashboarding: View your 30-year-old Modbus energy analyzer data on the same dashboard as your brand-new wireless vibration sensors. AgPM creates a single pane of glass for your entire operation.

Don't let your legacy assets remain silent. Contact Skysens today to define the best integration strategy for your facility.