How Skysens AgPM works with existing automation systems?

Cloud technologies have initiated a digital transformation in industrial companies. Key stakeholders seek to optimize existing automation systems for better control, data intelligence, security, and efficiency with the analytics and AI capabilities that these cloud-based platforms provide. As a cost-saving measure, industrial companies seek to transform and modernize existing industrial infrastructures with new platform capabilities and data points. However, many industrial companies struggle with integrating high-tech platforms and sensors into existing control systems. According to McKinsey, the lack of digital capabilities is the main struggle that most companies face when integrating conventional automation setups with smart analytics solutions. This article explores how Skysens Agile Predictive Monitoring Platform (AgPM) helps overcome automation integration obstacles.

Why is industrial automation integration important?

Stakeholders in major industries can no longer afford to pursue automation without considering integration plans. Instead, they must treat both automation and integration as opposite sides of the same coin in their modernization plans. By striking a balance between both areas, companies will achieve these benefits.

Improves system efficiency

Industrial facilities grappling with rising costs and decreasing margin strives to optimize efficiency to the most refined level. With disparate automation systems, technical operators must coordinate workflow with separate data points. This requires additional training and switching between procedures, which leads to human errors and productivity loss. By integrating diverse automation systems in the industrial facility into a single platform, technical operators become more efficient in supporting operational processes from a unified console and pinpointing root causes with very little effort. For example, the maintenance staff in the Istanbul Airport uses Skysens AgPM for cold chain, logistics, energy, and equipment monitoring for predictive maintenance efforts.

Reduces capital expenditure

As companies are pressed to modernize industrial equipment, they face the dilemma of discarding existing equipment with more advanced solutions. However, using a highly integrable data platform allows companies to avoid disposing of their existing automation assets. Instead, they can add a layer of smart analytics with or without additional wireless sensors for integration of hardware and software.

AI Implementation

Companies seeking to benefit from AI technologies such as machine learning and predictive analytics require ingesting a vast amount of process data into a data warehouse. Integrating existing automated systems to an intelligent data platform provides a standard pipeline that streams and consolidates industrial data for AI driven analytics.

What are the challenges when integrating industrial automation systems?

Despite growing awareness of importance of integrating automation systems, many industrial companies fall short of their goals because of several issues.

Lack of technical expertise

As mentioned, merging conventional industrial systems with emerging networks requires specific skill sets and knowledge. This means up-skilling technical operators through training or hiring new technical specialists for industrial companies. Likewise, industrial equipment vendors must overcome the difference in network protocols to enable total integration of all systems to implement their solutions.

Data diversity

Expanding industrial automation with IoT capabilities introduces diverse data types that require new data storage and middleware solutions. For example, system administrators must cater to structured, semi-structured, and unstructured data generated by IoT data points. This involves integration with different types of data warehouses, where ingested data are put through proper ETL processes before they fuel business intelligence tools.

Security concerns

Integrating automation systems with new data endpoints increases attack surfaces and security risks. As IoT sensors lack the computing resources to provide robust protection, companies must employ additional measures to secure data transmission within the automation network. For example, industrial plants use Skysens proprietary secure technologies to ensure data integrity while scaling up their data capabilities.

How Skysens AgPM works with conventional automation systems?

Skysens AgPM is a comprehensive data platform that provides end-to end integration with existing industrial systems. It also allows industrial companies to merge legacy systems with scalable IoT-enabled devices without complicated setups. The platform helps companies overcome common integration challenges with these distinct characteristics.

Integrability

Skysens AgPM is highly integrable with commonly-used automation systems such as SCADA. These automation systems are prevalent in all types of industries, although with limited data analytics capabilities. Skysens AgPM allows these automation systems to function beyond their traditional boundaries. With the AgPM platform, SCADA-based systems can perform data analytics with unlimited flexibility with external systems with connections such as Modbus TCP and OPC. Technical operators can also integrate legacy systems with IoT sensors via protocols like MQTT. AgPM’s interoperability also extends to existing software platforms, with the aid of communicating frameworks like REST API, HTTP POST, and Custom XML integrations. With these integration capabilities, any existing legacy industrial monitoring system can become smarter by allowing users to share data easily, flexibly, and securely.

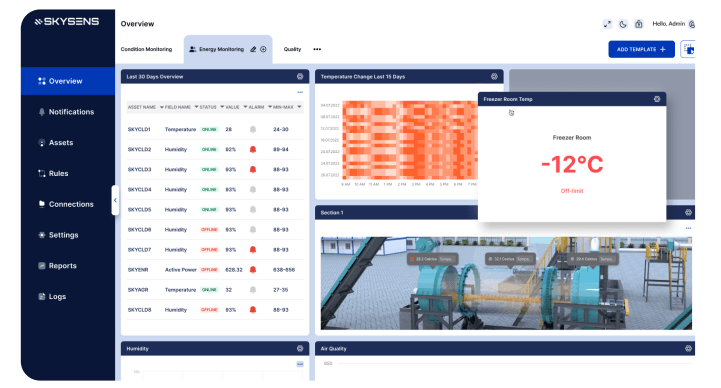

Data visualization improvement

Automated systems have traditionally functioned to replace laborious chores with robotics and machines. Skysens AgPM injects a degree of smartness into the existing automation setup. It provides an analytic layer that consolidates, processes, and analyzes automation data to manifest smarter systems. For example, the AgPM platform generates smart alerts based on pre-configured parameter thresholds with easy-to-use, drag-and-drop visualization. It empowers the entire enterprise IT system with cutting-edge data collaboration capabilities.

Scalability

Skysens AgPM supports your organization’s expansion effort by eliminating costly cabling expenses, middleware software, and retaining existing equipment. It allows technicians to perform no-code integrations to existing data silos and deploy low-cost sensors in a plug-and-play manner easily at low cost. These systems then communicate with existing industrial monitoring systems via data adapters and one touch integrations with unlimited scalability.

How companies benefit from integrating automated systems with Skysens AgPM

Industrial companies that adopted Skysens AgPM as a part of their automation integration plan have reported benefits in several areas.

Improves process efficiency

Skysens AgPM platform enables companies to improve asset performance and energy efficiency by 20%. It does so by augmenting the existing system with realtime data ingestion and processing capabilities. This allows system operators to monitor industrial systems with better clarity and precision. Timely data ingestion also enables operators to respond promptly to operational issues and improve OEE, process quality, and efficiency simultaneously on a single system.

Expand data sources and storage

Technical operators use Skyeses AgPM to overcome the limits of existing storage infrastructure for SCADA systems. The AgPM platform provides ample storage that works not only for structured data but also semi and unstructured data. Instead of limiting historical data to a couple of months, AgPM expands the storage capabilities of existing industrial systems by multiple folds.

Data sharing and reporting

Skysens AgPM facilitates data sharing amongst managers, operators, and other personnel in an intuitive and secure environment with no code and MQTT and REST API end points. Technical staff or in house analysts uses a no-code interface to generate visual-rich reports consolidated data from different automation systems and reduce data analytics and further AI development costs by 80%.

Cloud independent

Automation integration does not always require public cloud migration. Some systems are required to function in an isolated domain to ensure operational reliability, low latency, and security. Skysens AgPM makes offline integration possible. It supports on-premise edge deployment, where data is collected and processed at the immediate data source such as an industrial PC or small server.

Conclusion

Skysens AgPM is integral in enhancing the smart capabilities of existing SCADA and DCS automation systems. It allows easy data integrations, implementation of localized instrumentation with cost- effective sensors and introduces AI-driven analytics to legacy systems. System integrators can leverage Skysens AgPM to fill the missing gap between existing automation systems and ERP/MES solutions and meet C-management requirements.